focused on environmental, economic, and social responsibility

SUSTAINABILITY

efficiency is key

Focused on making the world a better place

We developed the D-Tech Rotary Steerable ESG strategy with a focus on creating an industry-wide level of ecological efficiency. We are constantly developing plans and processes to achieve further improvement in all areas.

At the core of our sustainability efforts is a holistic approach that considers the energy input required for materials and manufacturing processes, compared to the overall lifecycle cost. Our entire team is dedicated to continually enhancing our sustainability practices to create a better future for generations to come.

reducing energy consumption

The D-Tech team has implemented multiple initiatives to provide a more sustainable workplace at all our locations.

- Electrical switch movement sensors to ensure energy is only used when needed.

- Our labs prioritize energy efficiency and safety. Testing ovens are equipped with automatic power control systems, ensuring that energy is conserved while also minimizing health, safety, and environmental risks.

- Testing equipment, such as our shock machine, is enclosed to reduce noise emissions in the shop, creating a quieter and more comfortable work environment.

- We embrace sustainable practices in our manufacturing processes, such as lead-free soldering techniques and utilizing rework methods, compliant with our quality program.

- We're investing in advanced technologies like 3D printing, which drastically reduces manufacturing-associated scrap and allows for faster design changes with less waste.

- We're optimizing material selection to extend product lifecycles while balancing cost and benefit considerations. For instance, we're investing in sustainable materials that last significantly longer, ultimately reducing the overall lifecycle cost and environmental impact.

- We work with suppliers to create a closed-loop, sustainable manufacturing process.

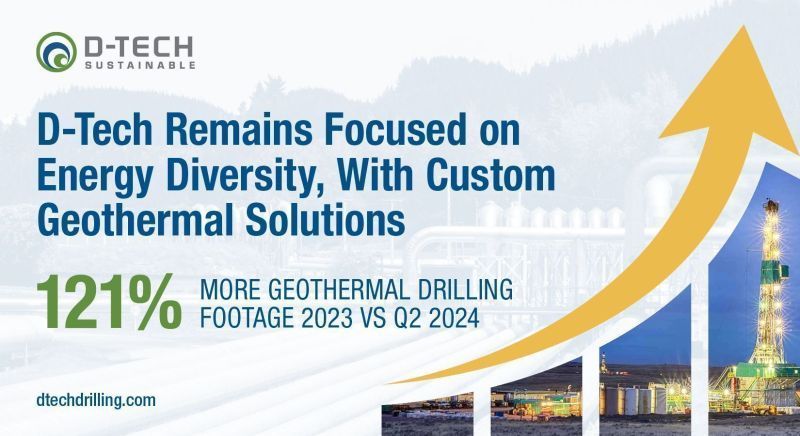

check out ouR geothermal initiatives